[December 2023] - The above events are some of the scenes on on-site Emergency Response Plan (ERP) simulation in Material Building......

[November 2023] - On October 24 2023, GMF again held the 22nd episode of Safety Interactive by presenting as speaker......

[October 2023] - Garuda Indonesia hosted Safety Day 2023 in the auditorium of the Garuda Management Building (GMB)......

[September 2023] - At the end of June 2023, Vietnam's civil aviation authority (CAAV) decided to temporarily suspend GMF authorization certificate No. VN-336NN/CAAV, CAAV assessed that......

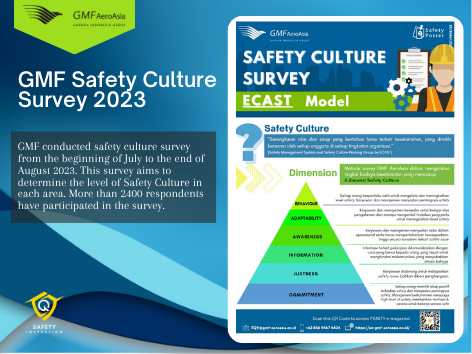

[August 2023] - Safety Inspection again conduct a Safety Culture Survey in the 2023 period. The survey took place from the beginning of July to the end of August 2023 and was attended by 12 production and support stakeholder offices at GMF. The enthusiasm of employees and structural staff can be seen from the participation of all parties......

[July 2023] - One of the implementations of the Safety & Quality Policy at GMF, the Safety Inspection unit consistently conducts safety engagement every month with the aim of maintaining a safety-positive culture. During the period of January to July 2023, GMF has conducted......

[June 2023] - The European Union Aviation Safety Agency, EASA, conducted an on-site audit at GMF from 19 - 20 June 2023......

[May 2023] - The United States Civil Aviation Authority, the Federal Aviation Administration (FAA), conducted an audit at GMF as part of the renewal certification agenda. FAA auditors, Jesus R. Gonzales and Gabriel Serano conducted an audit at GMF from May 8 to 15, 2023......

[Apr 2023] - Garuda Group Safety Board (GGSB) is a group consisting of Garuda Indonesia Group, namely Citilink Indonesia, GMF AeroAsia, Gapura Angkasa, Aerowisata Food, Aerowisata Transport, and Garuda Daya Pratama Sejahtera. GGSB aims to strengthen safety......

[Mar 2023] - GMF Safety Inspection (TQY) conducted an offline Aircraft Maintenance - Safety Management System (AM-SMS) training for 20 selected personnel namely SAG Chairman (VP), Senior Manager, and Manager from Cengkareng and multibase areas. Mr. Andi Fakhrurrozi as CEO of GMF officially opened.....

[Feb 2023] - PT. Garuda Maintenance Facility Aero Asia Tbk held the Quality System Management Review (QSMR) and Safety Management Review (SMR) second semester of 2022 on January 31st, 2023, which were attended by the GMF Board of Directors,.....

[Jan 2023] - The Quality Assurance and Safety Department held a Maintenance Line Operation Safety Assessment (MLOSA) Training Batch X on January 18 - 19, 2023 at Tidore Room.....

[Dec 2022] - MLOSA is a tool to identify hazards earlier during the aircraft maintenance process.....

[Nov 2022] - The Civil Aviation Safety Authority (CASA) has finished carrying out the Surveillance agenda at GMF AeroAsia.....

[Oct 2022] - GMF Culture Festival 2022 is an event that aims to align the culture of GMF employees with the values of Indonesian SOEs Values.....

[Sep 2022] - The Quality Assurance and Safety Department held a Aviation Maintenance - Safety Management System (AM-SMS) Training Batch XVIII.........

[Aug 2022] - PT GMF AeroAsia Tbk held the first semester of Quality System Management Review (QSMR) and Safety Management Review (SMR).........

[July 2022] - The safety engagement agenda can motivate all personnel to implement safety in the workplace.........

[June 2022] - Safety sharing is a method to remind personnel of the importance of safety at work and to increase knowledge and awareness related to safety........

[May 2022] - In Safety Risk Management (SRM), there is one tool that can increase the Safety Level, namely by conducting an Internal Risk Assessment or commonly known as an IRA........

[April 2022] - In the first quarter 2022 was wrapped up by SAG Quarterly conducted by each SAG.......

[March 2022] - Risk management is an important aspect of a company's business strategy when it comes to change management.......

[February 2022] - Safety Performance Indicator (SPI) is an indicator made by a Service Provider such as GMF......

[February 2022] - PT Garuda Maintenance Facility Aero Asia, Tbk held a second semester Quality Management System Review (QSMR) and Safety Management Review (SMR) on January 20th, 2022.......

[January 2022] - The Safety Action Group Maintenanance Planing (SAG TF) was officially formed on January 28, 2022......

[January 2022] - In January 28, 2022, Quality Assurance and Safety (TQ) Department was organizing Safety Action Group (SAG) online Workshop......

[December 2021] - We must also increase inspections and ensure the airworthiness of aircraft and maintenance personnel on duty during the NATARU 2022......

[November 2021] - PT GMF AeroAsia in terms of implementing safety activities, the role of a leader will denitely inuence the work process to meet the company's safety targets......

[October 2021] - Now, PENITY has been present for 13 years to share safety knowledge and information.....

[September 2021] - In 2021, PT Garuda Maintenance Facility AeroAsia Tbk made changes to the organizational structure of the Safety Management System (SMS).....

[August 2021] - The Directorate of Airworthiness and Aircraft Operation (DKPPU) conducted a Safety Audit for renewal certification of 145D-1 PT Garuda Maintenance Facility AeroaAsia Tbk....

[July 2021] - I Wayan Susena as CEO of GMF and also as Accountable Manager advise that implementation of Safety and Quality must be understanding by each GMF heroes for improvement....

[June 2021] - The AM-SMS training is part of a continuous safety improvement process at PT Garuda Maintenance Facility Aero Asia Tbk where this training aims to develop a new Safety Messenger....

[May 2021] - The Federal Aviation Administration (FAA) conducted a renewal audit of GMF from May 5 to June 2, 2021. Due to the COVID-19 pandemic, the audit was conducted online....

[April 2021] - GMF President Director, I Wayan Susena expressed his appreciation to the government, parent company, and employees. "We would like to thank the government, the Ministry of BUMN, and Garuda Indonesia for facilitating and organizing the implementation of this vaccination....

[March 2021] - PT. GMF Aeroasia, Tbk has never stopped implementing improvements. Periodically every month the Safety Inspection unit performs a Safety Risk Management analysis...

[February 2021] - PT GMF AeroAsia, Tbk held a second semester Quality Management System Review (QSMR) and Safety Management Review (SMR)...

[March 2020] - The coronavirus disease (COVID-19) has been identified as the cause of an outbreak...

[February 2020] - PT GMF AeroAsia, Tbk held a second semester Quality Management System Review (QSMR)...

[February 2020] - As part of its commitment to implementing an information culture that is also part...

[February 2020] - PT GMF AeroAsia, Tbk held a Safety & Health Day (SHD) 2020 on 03 - 04 February 2020...

[September 2019] - PT GMF Aeroasia Tbk won an award at the prestigious MRO Asia Pacific event on ...

[August 2019] - Before we talk about the definition of fulfilling Quality & Safety Compliance (QSC)...

[March 2019] - PT GMF AeroAsia Tbk won the Zero Accident Award from the Banten Provincial Government...

[March 2019] - PT GMF AeroAsia held the second semester Quality System Management Review (QSMR) and Safety Management Review (SMR) at the Audiotorium Hangar 4, March 18, 2019...

[February 2019] - On Tuesday, February 19, 2019, at the Samosir room, Hangar 4, a joint commitment was signed for the implementation of MLOSA...

[February 2019] - The Safety Action Group Narrow Body Base Maintenance (SAG TJ) was officially formed on February 19, 2019...

Best IOR Awards

Best Internal Occurence Report Award this semester was given to these 3 person who report hazards around their work area in order to achieve safer place for work. Read More

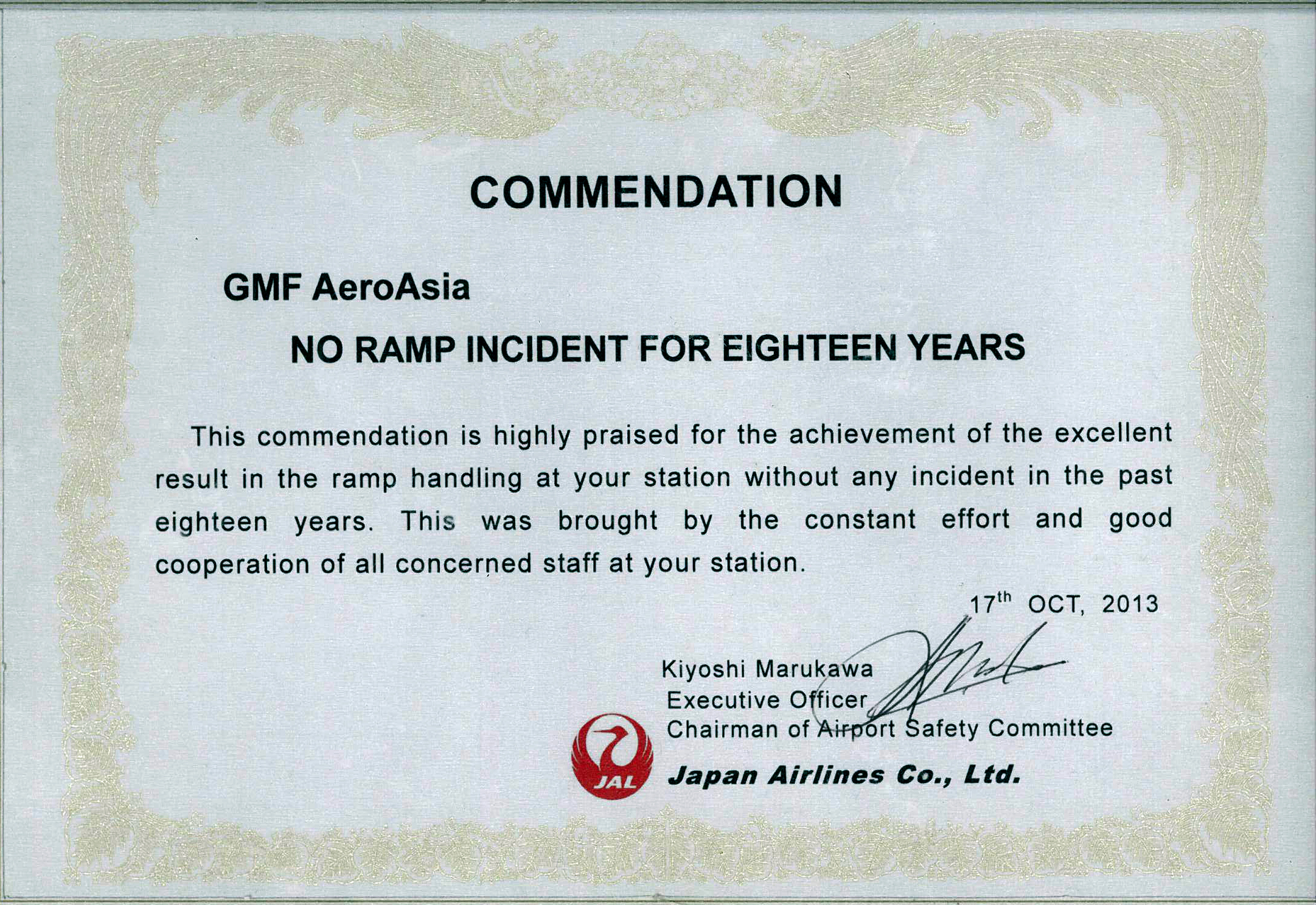

Commendation JAL

JAL (Japan Airlines) gave the Commendation to GMF AeroAsia related No Ramp Incident For Eighteen Years in October 2013. This award should motivate us more to work safe. And give the best quality to our work. Read More

Safety Magazine (PENITY)

PENITY is our free safety magazine published by Quality Assurance & Safety unit every month. You can download these magazines for free. Read More

Safety And Quality Policy

To achieve a level of safety and quality as required by aviation regulation and customer's requirements, the management and other personnel are committed to four Safety And Quality Policies. Read More

DO & DON'T Policy

About Company

With over 60 years of experience, Indonesia-based GMF AeroAsia has emerged today as the largest aircraft maintenance in Indonesia as well as the MRO provider of choice. Read More